Experiment with Searle’s apparatus to determine Young’s modulus of a wire by measuring stress, strain, and extension, and verifying elasticity with precision.

Apparatus

Searle’s apparatus includes, micrometer screw gauge, a meter rod, two identical wires, a spirit level, and kilogram weights.

Observations

-

Length of wire (L) = …… cm

-

Pitch of screw gauge = …… mm

-

Number of divisions on circular scale = …… mm

-

Least count of screw gauge = …… mm

-

Zero error = …… mm = …… cm

-

Mean zero error = (i) …… mm (ii) …… mm (iii) …… mm

-

Zero correction = …… mm

-

Diameter of wire = …… mm

-

Mean observed diameter = (i) …… mm (ii) …… mm (iii) …… mm

-

Radius of wire (r) = …… mm

-

Breaking stress for wire material = …… kg.wt/sq.cm

-

Maximum load = …… kg.wt

-

Micrometer reading = …… mm = …… cm

-

Least count of micrometer = …… mm = …… cm

Experiment with Searle’s apparatus to determine Young’s modulus of a wire by measuring stress, strain, and extension, and verifying elasticity with precision.

| Extension for 2 kg.wt | Mean | Micrometer reading of circular scale |

Additional Load in kg.wt | No.of Obs |

| 123456 |

Calculation:

Mean extension for 2 kg.wt = =mm

Force =2 kg.wt =2100

981 dynes

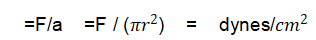

Stress

Longitudinal strain =l/L

Young’s modulus (Y) =stress /longitudinal strain =FL/(al)

Percentage error = %

Procedure

To determine Young’s Modulus, suspend two identical metal wires, EF and GK, from a rigid support.

Attach the lower end of wire EF to frame R, and the other wire GK to frame P. Hang a heavy load W with frame P to keep wire GK stretched.

Next, measure the wire length L from the suspension point to the attachment on Searle’s apparatus.

Use the screw gauge to measure the diameter of the experimental wire at different points. Then calculate the cross-sectional area.

When the hanger H is loaded, the frame R moves down relative to P. Adjust the micrometer screw M until the spirit level becomes horizontal. Record the reading.

Add a 1 kg weight to the hanger, causing further stretch. Again, rotate the screw gauge head until the bubble in the spirit level is centered. Note the new reading.

Repeat this process, increasing the load up to 5 kg, and record all readings both during loading and unloading.

Take the mean values for each load.

To find the extension for 2 kg, subtract alternate readings and take their mean.

Finally, use the calculated values to determine Young’s Modulus (Y) of the material.

Precautions

-

Note the least count of both the micrometer and screw gauge carefully.

-

Take readings for both loading and unloading.

-

Ensure the wire is straight, free from kinks and bends.

-

Do not load beyond one-third of the wire’s breaking stress.

-

Keep the spirit level perfectly horizontal for accurate readings.

Viva Voce

Q1. What is Young’s Modulus?

Ans: It is the ratio of stress to longitudinal strain.

Q2. What is the yield point?

Ans: The point beyond which the wire begins to flow despite a constant load.

Q3. Define stress and strain.

Ans: Stress is the deforming force per unit area, while strain is the ratio of the change produced by the deforming force to the original length.