Experiment to find the wire area or sphere volume using a micrometer screw gauge with pitch, least count, and zero error correction.

Apparatus

-

Micrometer screw gauge

-

Wire or metallic sphere

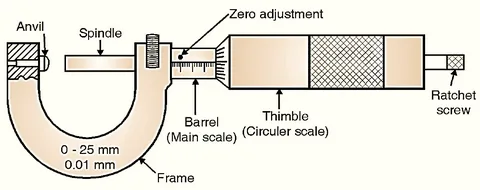

Diagram

Introduction

The micrometer screw gauge is used to measure the thickness of very thin metal strips or the diameter of a sphere. It works on the principle of a screw. The instrument has a U-shaped frame, a fixed end, and a movable spindle with uniform grooves.

The cylinder has a linear scale marked in millimeters and a circular scale with 50–100 divisions. The circular scale measures fractions of a revolution. The linear scale shows the number of full revolutions. The reading of the circular scale is noted against a reference line.

The device can measure up to 0.01 mm, which is why it is also called a micrometer.

Important Concepts

Pitch

The pitch is the distance the screw advances in one complete rotation.

Zero Error

When the spindle and the anvil touch, the zero error is determined by the alignment of the circular scale with the index line.

Positive Zero Error

If the zero line lies below the index line, the error is positive:

Zero Error=+(No. of divisions)×L.C.\text{Zero Error} = + (\text{No. of divisions}) \times \text{L.C.}Zero Error=+(No. of divisions)×L.C.

Negative Zero Error

If the zero line lies above the index line, the error is negative:

Zero Error=−(No. of divisions)×L.C.\text{Zero Error} = – (\text{No. of divisions}) \times \text{L.C.}Zero Error=−(No. of divisions)×L.C.

Procedure

-

Determine the pitch and least count of the screw gauge.

-

Measure the zero error if present.

-

Place the wire between the spindle and anvil. Turn the screw until the wire is gently pressed.

-

Record the linear scale reading RRR and the number of circular divisions coinciding with the index line nnn. Multiply nnn by the least count to get yyy.

-

Add yyy to RRR and apply zero correction to find the corrected diameter.

-

Repeat at three different points of the wire. Calculate the radius r=d/2r = d/2r=d/2 and the cross-sectional area A=πr2A = \pi r^2A=πr2.

-

For the sphere, measure the diameter, calculate the radius, and then compute the volume using V=43πr3V = \frac{4}{3} \pi r^3V=34πr3.

Observations and Calculations

= 0.5 mm/ 50

= 0.01mm

Diameter of wire

| No.of Obs | Linear scale reading R |

Circular scale reading n |

Fraction to be Added Y = n L.C. |

Observed diameter = R + y |

Corrected Length Z.C |

| mm | div. | mm | mm | mm | |

|

1 2 3 4 |

Mean diameter = d = ………… mm

Radius of wire = r = d/2 = …….. mm

Area of cross-section of wire = A = π r3 = ……. mm2

Result:

Area of cross-section of wire =A = ……. mm2

| No.of Obs | Linear scale reading R |

Circular scale reading n |

Fraction to be Added Y = n L.C. |

Observed diameter = R + y |

Corrected Length Z.C |

| mm | div. | mm | mm | mm | |

|

1 2 3 4 |

Mean diameter = d = ………… mm

Radius of sphere = r = d / 2 = …….. mm

Volume of sphere = V = 4 / 3 r3 = ……. mm3

Result:

Volume of sphere = V = ……. mm3

Precautions

-

Apply zero error correction in all readings.

-

Do not overtighten the screw.

-

Always turn the screw in the same direction.

-

Ensure the instrument is clean before use.

Viva Voce

Q1: What is the pitch of a screw gauge?

Ans: The pitch is the distance the spindle advances in one full rotation of the circular scale.

Q2: What is a screw gauge?

Ans: It is an instrument used to measure diameters or thickness accurately.

Q3: Calculate the least count if the circular scale has 100 divisions.

Ans:

LC=PitchNo. of divisions=1 mm100=0.01 mm\text{LC} = \frac{\text{Pitch}}{\text{No. of divisions}} = \frac{1 \text{ mm}}{100} = 0.01 \text{ mm}LC=No. of divisionsPitch=1001 mm=0.01 mm